Slitter Machines in the Industry

Slitter machines are vital tools in the converting industry and are also widely utilized in manufacturing sectors where large rolls of material need to be processed into smaller, manageable widths. These machines address the need for materials to be precisely slit and efficiently prepared for further use.

Industries such as packaging, printing, textiles, and electronics rely heavily on slitter machines to tailor materials to specific dimensions essential for their operations. This article delves into the intricacies of slitter machines, particularly the slitter rewinder, examining their functionality, components, and diverse applications.

What is a Slitter Machine?

A slitter machine is a device designed to cut or slit large rolls of material, such as paper, plastic film, foil, or fabric, into narrower strips. Most modern slitter machines integrate a rewinder, creating a streamlined system known as a slitter rewinder.

This machine combines unwinding, slitting, and rewinding into a high-speed and precise operation, enabling rapid processing of materials while ensuring the slit strips are neatly wound onto smaller cores.

By optimizing these processes, slitter rewinders have become indispensable in industries requiring tailored material sizes for both industrial and consumer applications.

How Does a Slitter Work?

Quick Answer

A slitter machine unwinds large rolls of material, cuts them into narrower strips using precision blades, and rewinds the strips onto smaller rolls for further processing or use.

Detailed Explanation

The process begins with the master roll being unwound, where tension and alignment are carefully managed to prevent wrinkles or slack.

The material then passes through the slitting section, where it is cut into narrower strips using precision cutting tools like rotary shear blades, razor blades, or crush cutters. The choice of cutting method depends on the type of material and its intended application.

Finally, the slit material is rewound onto individual cores in the rewinding section, creating neat, uniform rolls. This continuous operation ensures high-speed production while maintaining consistent quality, making slitter rewinders indispensable for efficient manufacturing workflow

Structure and Components of a Slitter Machine

Section | Purpose | Key Components |

|---|---|---|

| Unwinding | Prepares the master roll for processing by ensuring stability, proper tension, and alignment. | Unwind Stand, Tension Control System, Edge Guide System |

| Slitting | Cuts the material into narrower widths using precision cutting tools and mechanisms. | Knives and Blades, Knife Holders, Slitting Mechanism, Adjustment Features |

| Rewinding | Collects the slit material into smaller rolls, ensuring uniform winding and quality. | Rewind Shafts, Tension Control System, Turret System, Lay-on Rollers |

1. Unwinding Section

- Unwind Stand: Supports the large roll during processing, ensuring stability and consistent feeding into the machine. Some designs include shaftless stands, which streamline loading and unloading by allowing rolls to be directly mounted, reducing manual effort and improving operational efficiency.

- Tension Control System: Regulates the material’s tension during unwinding, preventing common issues like wrinkles or slack. Advanced tension systems adapt dynamically to material properties, ensuring a smooth and stable process for various types of materials.

- Edge Guide System: Aligns the material with high precision, using sensors to detect and correct misalignment in real time. This ensures the material is fed into the slitting section accurately, reducing waste and improving overall efficiency.

For more demanding applications, advanced solutions like Yo Den's Jumbo Roll Slitter UHS-II elevate these core features. This model integrates a shaftless unwind stand for faster roll changes and automatic tension control with S-wrap transport and vacuum rollers, ensuring precise feeding and wrinkle-free operation for heavy rolls up to 1500 mm in diameter.

We recommend the UHS-TR, a four-axis non-stop center winding machine, which integrates the differential shaft and pressure wheel to ensure efficient and high-quality winding.

▲Razor Slitting

▲Shear Cutting

▲Automatic Knife Positioning

2. Slitting Section

- Knives and Blades: These are the primary cutting tools, with options like rotary shear blades, razor blades, and crush cutters, chosen based on material properties and application requirements.

- Knife Holders: Secure the cutting tools and allow for precise adjustments to optimize cutting accuracy and reduce blade wear.

- Slitting Mechanism: Refers to the overall system and method by which the blades interact with the material. This includes blade movement, alignment, and cutting dynamics. For example, rotary shear mechanisms involve two blades working together like scissors, while razor systems cut by dragging a sharp blade across the material.

- Adjustment Features: Facilitate quick and precise repositioning of blades, allowing operators to adapt to different width requirements and material types efficiently. These features focus on setup flexibility and operational ease, ensuring minimal downtime.

By combining the slitting mechanism with effective blade positioning, the design ensures both the quality of the cut and the flexibility of operations. Yo Den's Wide Web Center Winding Slitter IND builds on these capabilities with an automatic knife positioning system that automates blade adjustments. This reduces setup time and enhances accuracy, especially for wide web materials like laminates and coated papers.

3. Rewinding Section

- Rewind Shafts: These shafts support and hold the cores while the material is wound onto them. By allowing for tension adjustments, rewind shafts ensure that rolls are evenly wound, preventing common issues like telescoping or uneven layers.

- Tension Control System: Maintains consistent pressure during the winding process, ensuring that each roll has uniform tightness. This is critical for avoiding defects such as slack or over-tightened rolls, which can impact downstream operations.

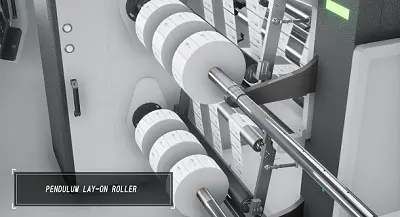

- Turret System: A rotating mechanism that repositions different rewind shafts to enable roll changes without stopping production. The turret rotates to bring a new core into place while finished rolls are removed, ensuring seamless transitions and uninterrupted workflow, which is crucial for high-speed operations.

- Lay-On Rollers: Apply controlled pressure during the rewinding process to ensure smooth, wrinkle-free rolls. These rollers are particularly beneficial for materials that are prone to creasing or deformation during high-speed operations.

The rewinding process in slitter machines is vital for creating usable rolls with consistent quality. Innovations like differential shafts, which allow individualized tension control for multiple rolls, play a crucial role in enhancing precision and efficiency. For instance, Yo-Den's Turret Slitter UHS-TR integrates advanced differential shafts and electro-pneumatic lay-on rollers to deliver superior winding performance. These technologies are especially valuable in high-demand industries such as flexible packaging and label manufacturing, ensuring that the final product meets stringent quality standards while maximizing production efficiency.

Conclusion

Slitter machines are essential for processing materials into specific sizes with speed and precision, supporting industries like flexible packaging, label manufacturing, textiles, and electronics. Advanced features, such as tension control, differential shafts, and automatic knife positioning—pioneered by Yo Den—ensure consistent quality and operational efficiency.

Yo Den offers advanced, customizable solutions tailored to meet your specific production needs. Don't let outdated equipment slow your production. Contact us today to discover how our solutions can elevate your operations